The optical screening machine is a non-contact continuous detecting device, which realizes continuous high-volume high-precision measurement by computer program identification, and liberates manpower; it has the advantages of wide application range and high detection precision.

The basic principle of optical screening machine cleaning is to use the difference in particle size between wheat and impurities to remove impurities. The main working component of the screening equipment in which the particle size of wheat is expressed by length and width is the sieve surface. Commonly used sieve faces are punched screen surface, woven screen mesh, sieve hole has circular sieve hole, square sieve hole, rectangular sieve hole, different sieve surface and sieve holes with different shapes and different sizes have different effects on cleaning effect. . The optical screening machines we are talking about are generally used in industrial products. The main function is to distinguish the appearance and defects of the products.

With the development and innovation of the machinery industry, the development of the screening machine industry has gradually stabilized. So, do you know what the optical screening machine does? Can the optical image screening machine bring us benefits? The following small series will come to introduce you.

First, the advantages of optical image screening equipment and traditional manual comparison:

As the industry develops, the size and appearance requirements of the product are also higher. If artificial length inspection is used, the eye fatigue is low and the product detection efficiency is low and the precision is not high. The use of optical screening machines instead of artificial vision can greatly improve production efficiency and inspection accuracy, and reduce labor costs.

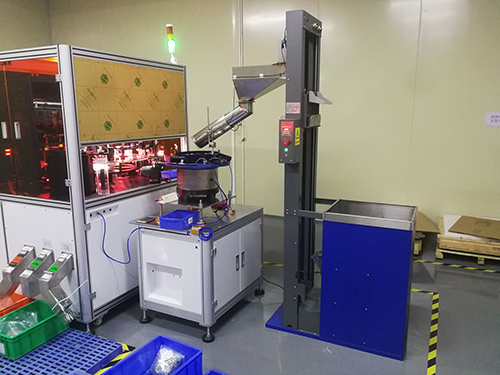

Second, eddy current optical screening machine product features:

1. Simultaneously detect the size, appearance, depth and mixing of different materials or heat treatment, image screening equipment, heat treatment hardness is up to standard;

2, can be used independently vortex, a number of bad exports, can be divided into poor size and poor hardness;

3, the fastest 300-500 per minute. The above is the introduction of what the optical screening machine is used, and the optical screening machine system can be applied to the production control process. When the production line produces the product, the quality monitoring of the production line can not only reduce the waste of raw materials, but also further effectively Control the production time. The use of automated optical screening machines not only reduces manpower, saves labor costs, optical sorter manufacturers, and significantly reduces human error detection, thereby improving work efficiency, improving product shipment quality, and enhancing product competitiveness.